Customization Options

Available customization options ranging from artwork to programming and packaging.

Cosmetic Design

Skip to Functionality

Plastic Color

The color of the enclosure for the remote control can be customized to meet most cosmetic requirements. Typically, the Pantone Matching System (PMS) or a RAS color code would be used to specify a particular color. The plastic resin used in the injection process would either be special ordered for the color chosen or the resin would be mixed in-house to color match to the selected color. Specialized colors, like metallic silver, can be painted on the plastic enclosure after injection.

Soft Touch Paint

A “soft-touch” paint can be added to the plastic post-injection to provide a softer, more rubberized texture to the remote control. After the soft-touch material is painted on the plastic, it is baked for a period of time to cure the paint and solidify the texture. This process can help make the surface of the remote more robust and improve both scratch and mar resistance.

Enclosure Printing

In many cases, the surface of the plastic enclosure can be screen printed with text, icons or other graphics. Typically, the Pantone Matching System (PMS) would be used to specify the color and either vector graphics or font styles can be used to specify the artwork.

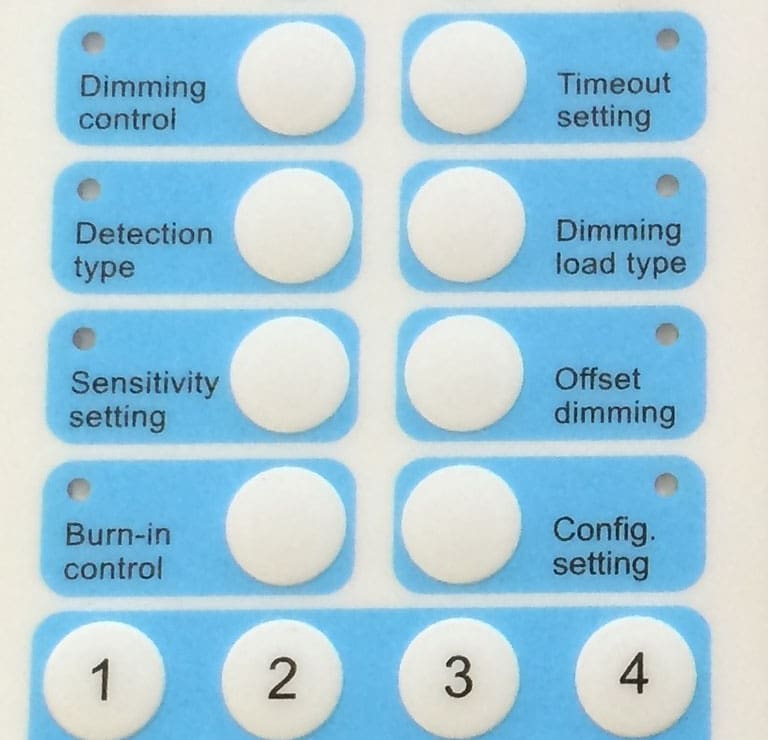

Keypad Colors and Artwork

The keypad of a remote control is typically made of rubber, plastic or an embossed polyester membrane material. The keypads can be fabricated and printed with any specified colors. Typically, the Pantone Matching System (PMS) would be used to specify a particular color for the keypad. Silicone rubber would be fabricated in a selected color, while plastic buttons are painted and membrane keypads are screen printed.

Keypad Printing

Keypad graphics, icons and text are screen printed onto the surface of the keypad. Pantone colors are used to specify the particular color and most vector-based graphics can be printed on the surface of the keypad. Artwork will be reviewed by a designer to ensure it is optimized for small form factor screen printing.

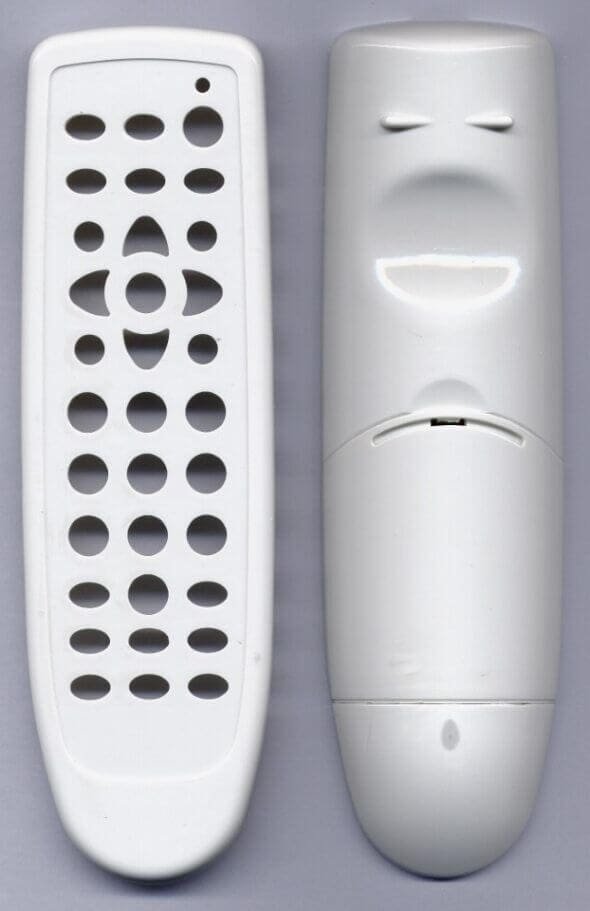

Full/Partial Overlays

An overlay is PVC, polyester or similar material label that is used to easily customize the key layout on a remote control. Many standard remote control enclosures are designed to utilize either a full or partial overlay, where either the entire keypad or a portion of the keypad is recessed from the top surface of the remote control. The overlay is a thick label that has the holes cut out for the buttons that will be used on a specific key layout. During the final assembly process, the rubber keypad of the remote control is cut, in order to remove any unused keys. The overlay is then attached to the recessed area on the front of the remote control and covers the holes in the plastic where the buttons were removed. The overlay can also be screen printed with any text, icons or other graphics to label the functions of the buttons, create logical key groupings or add branding/logos to the remote control. Similar to the plastic case and rubber keypad, a color code from the Pantone Matching System (PMS) would be used to specify the color(s) and either vector graphics or font styles would be used to specify the artwork.

Functionality

Skip to Packaging

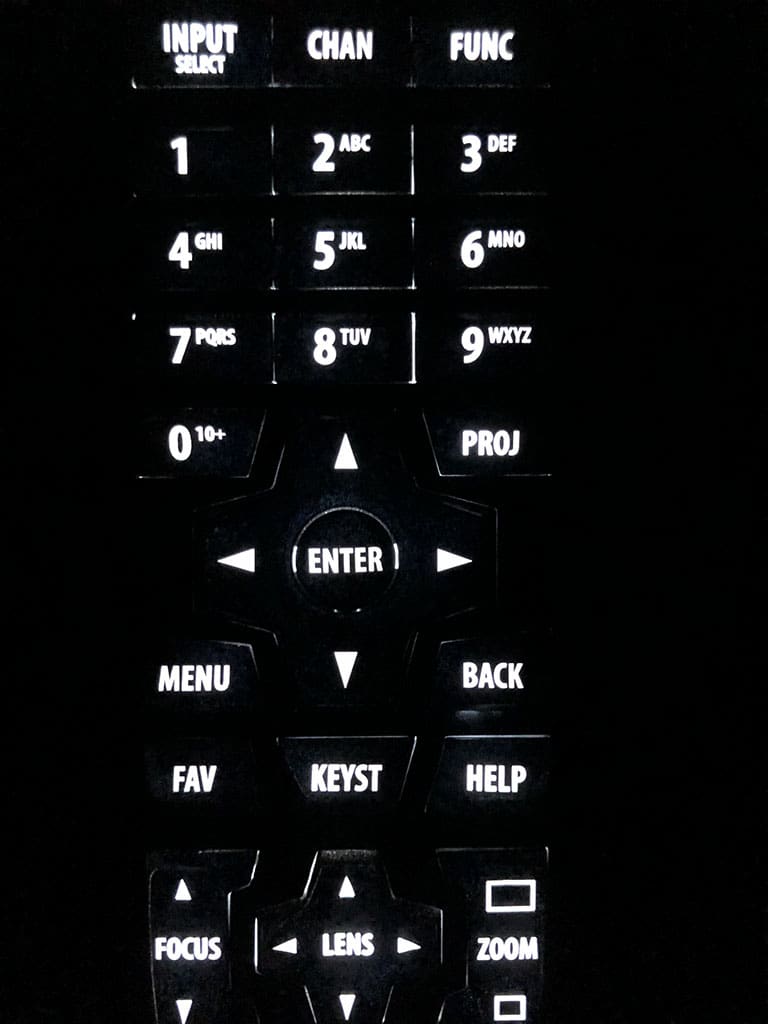

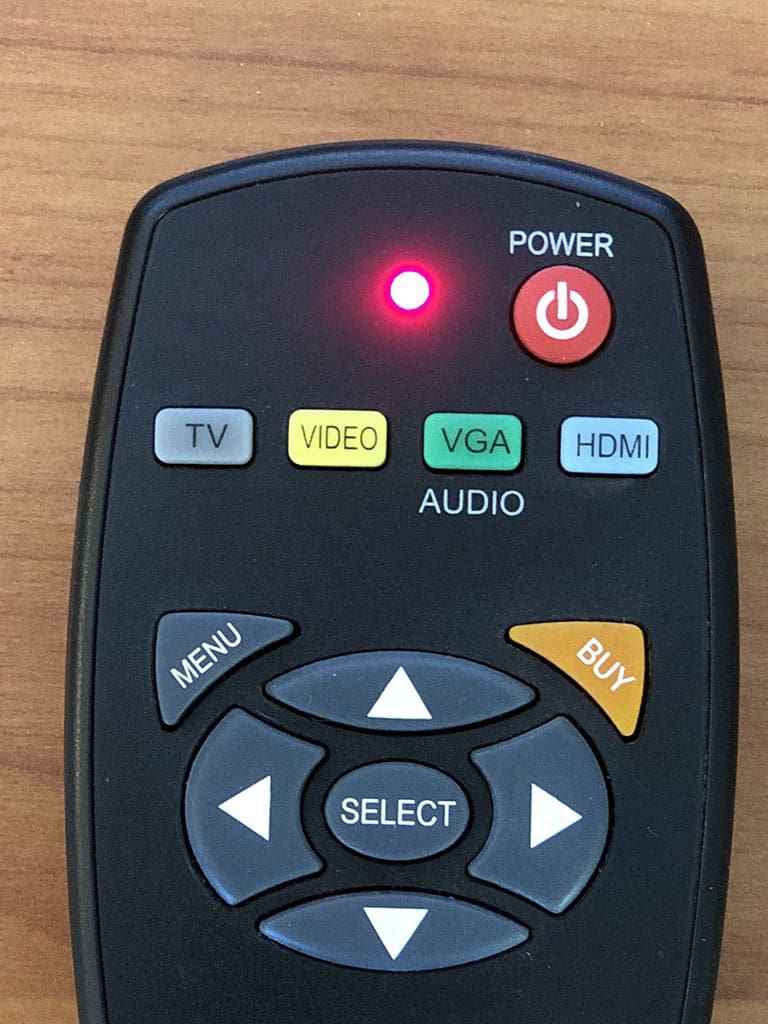

Button LED

A button LED can be placed on the circuit board next to a button location and with the use of a translucent rubber key, individual buttons can be illuminated. This is generally used to provide additional user feedback, like which device is selected on a Universal Remote Control or for specialized functionality.

Keypad Backlighting

For many standard enclosures, a new circuit board can be designed to incorporate LED keypad backlighting functionality. The keypad can be illuminated by Red, Green, White or Blue LEDs and the duration of time that the backlighting is on can be set in software on the microcontroller. Several different methods of activating the backlighting are available and include having the backlight turn on with any key press, a dedicated backlighting button or the use of a motion sensor or vibration sensor for automated use.

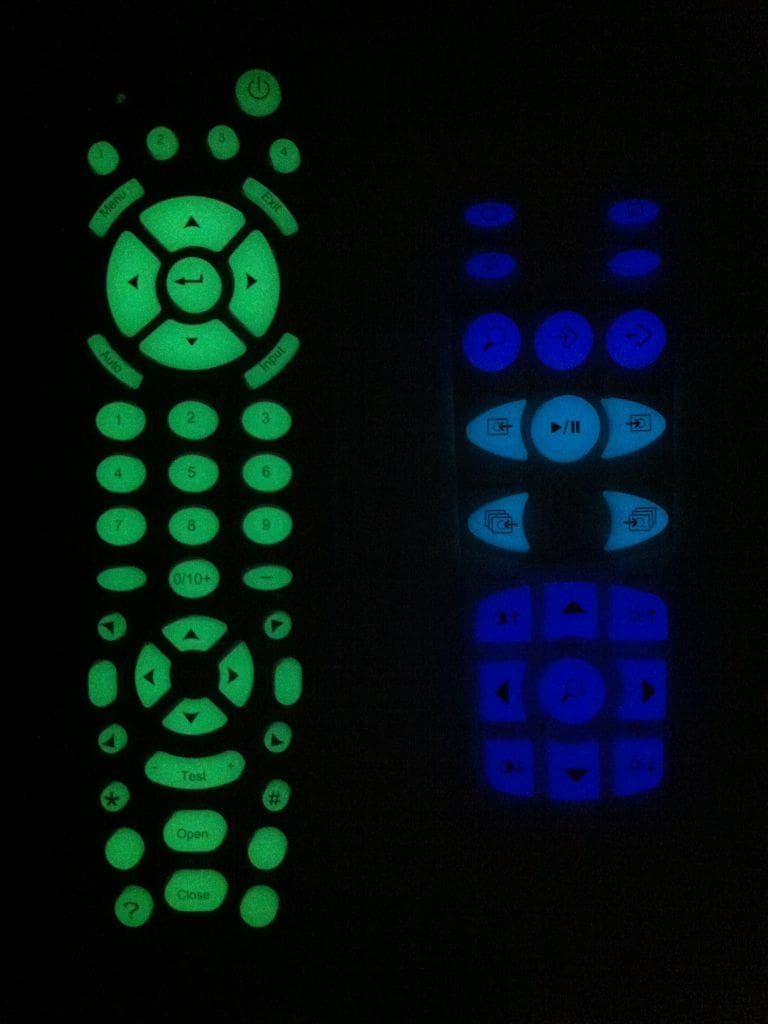

Luminescent Keypads

Keypads can be fabricated with a luminescent material to provide a “glow in the dark” type of effect. The standard glowing keypad color is a yellowish-green color, but other custom colors are available. High contrast artwork against a glowing keypad can provide the ability to use the remote control in low light environments.

Feedback LED

Many standard enclosures offer a feedback LED, which will blink any time that a button is pressed. This provides feedback to the user that the remote control is working properly and transmitting a code when a button is pressed. Feedback LEDs are typically red, but can be provided in other colors like green, blue or white.

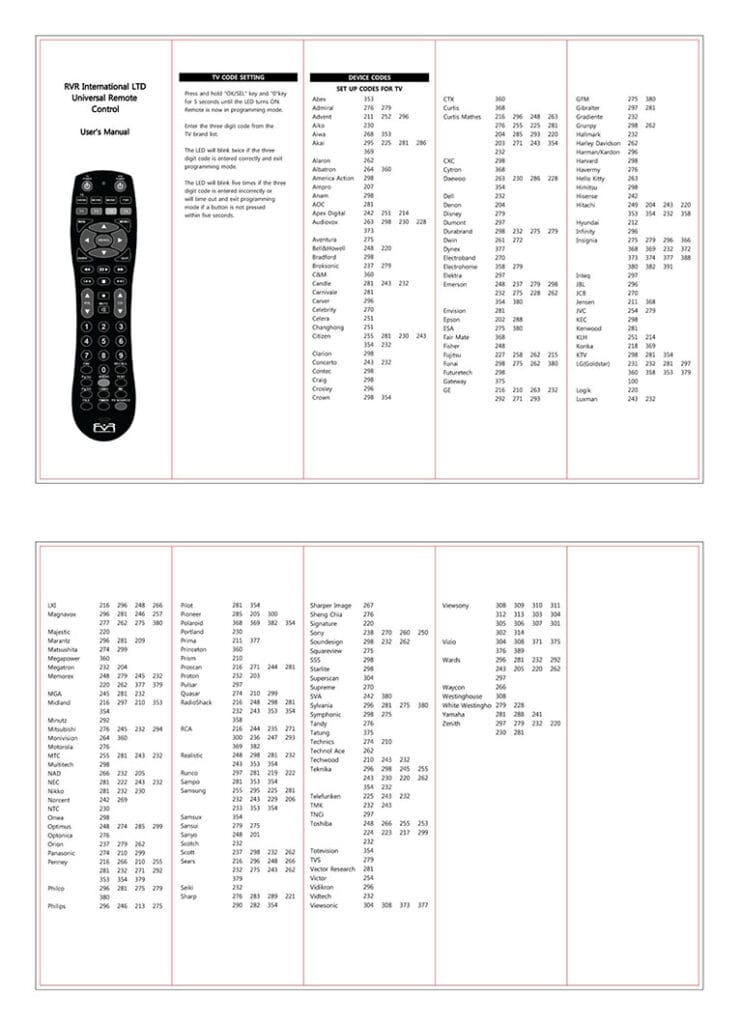

Universal Code Library

A “Universal Library” can be added to a remote control to provide enhanced functionality. Universal libraries include TV, DVD, STB/CAB and AUDIO devices. A common example of adding Universal library functionality would be to add a TV library to a video product to provide basic control over a TV (POWER, VOLUME, etc.) and provide a better user experience.

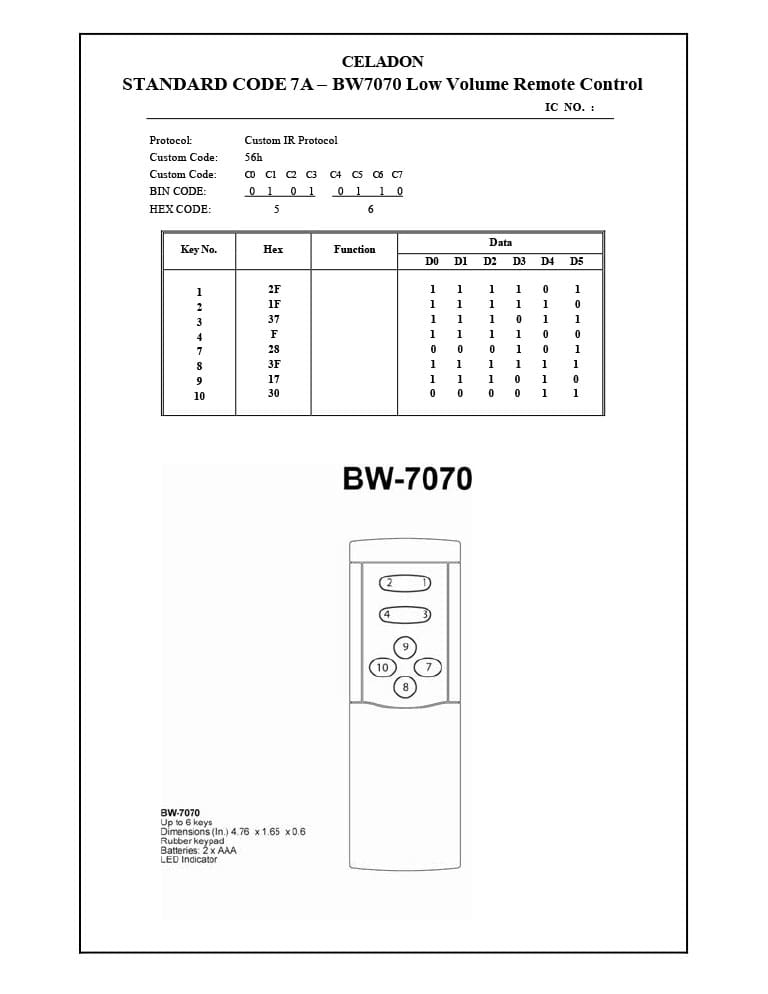

Dedicated Programming

A variety of programming options are available for any OEM remote control project. A remote control that has only a single code set and is only intended to control a single device would be considered a “Dedicated” remote control. The infrared protocol can be specified, along with the system code and command table to control an existing device or for a new product being developed.

Learning Functionality

Learning functionality can be used to supplement the codes of a Universal Library by adding additional codes to the remote control. The original remote control would be required to “teach” the IR codes to the device. The remote would have non-volatile memory to ensure that any learned codes would not be erased when batteries are replaced.

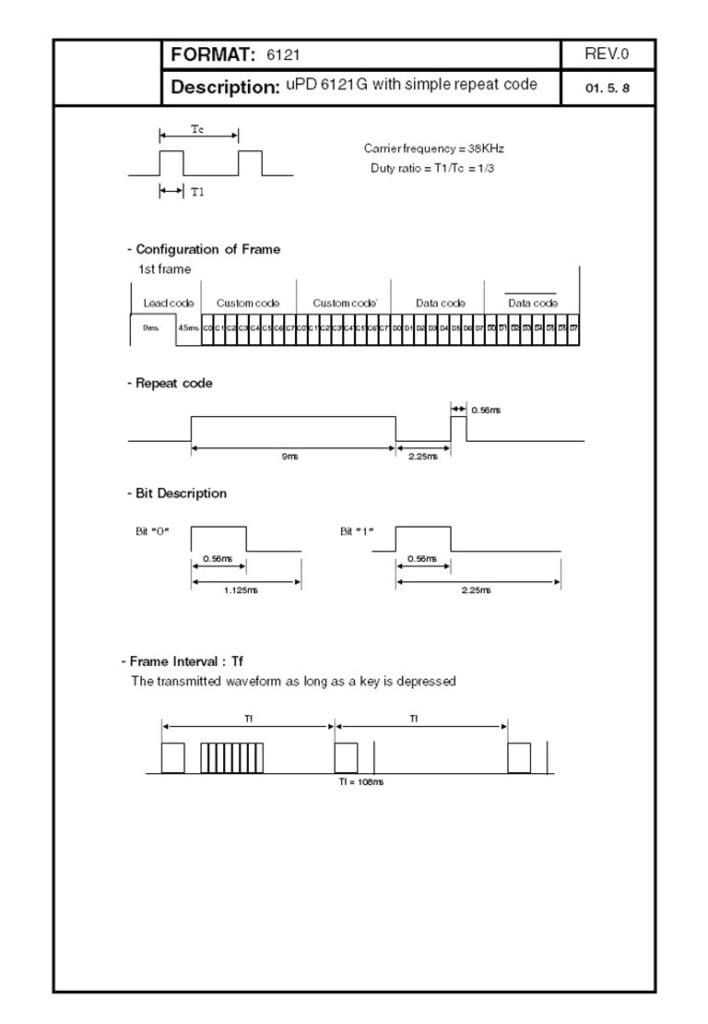

Custom Transmission Protocol

It might be desirable to use a unique transmission protocol for a remote control product. This protocol might have specialized functionality, like “key-up” bits, a unique carrier frequency or other features. Once the product requirements are defined, a protocol specification will be created and samples will be provided for final approval.

Addressability

In some cases, the remote control might require some type of system addressability. This is typically used in a scenario where multiple remotes would be used in the same environment. The addressability of the device can be implemented in several different ways including dedicated buttons on the remote, a more complex user setup function or having a unique address programmed during mass production.

Packaging

Skip to Cosmetic Design

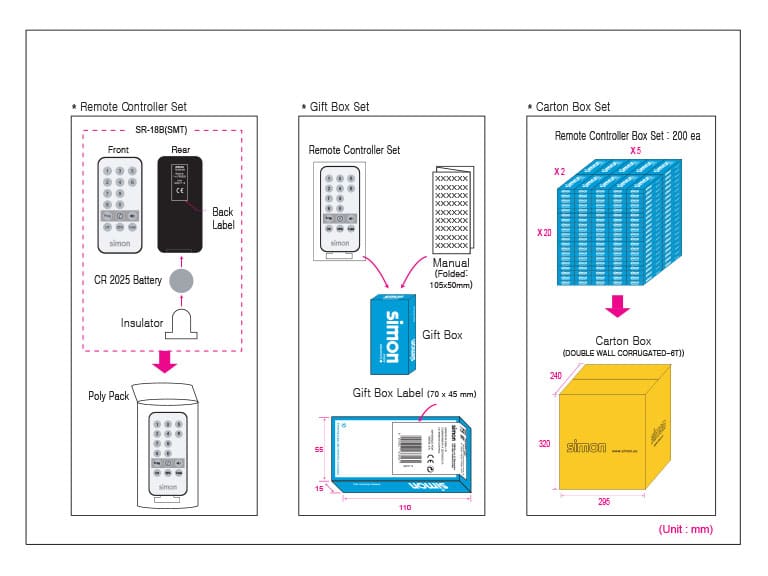

Manuals

Manuals can include with OEM production. Manual options range from a simple black and white printed page, multiple pages, color manuals, specialized folding or even CD-ROM.

Batteries

Batteries can be included with OEM products. Various types and brands of batteries are available. Batteries can either be inserted into the battery compartment with an insulator strip for easy activation of the product or simply placed in the same plastic bag as each remote.

Bulk Packaging

During mass production, OEM products can be kitted and packaged in many different formats. The typical method of packaging is called “Bulk Packaging”, where each product is placed into a plastic bag and then inserted into a cardboard sleeve within a shipping carton. This is the simplest and most cost-effective packaging method available.

Custom Packaging

Custom packaging options are available for OEM products. These options include custom gift boxes with specialized printing or labels, custom export cartons with specific sizes, colors and printing on the boxes. Other packaging options include clamshell and blister packs that could be used for retail display.