Custom Tooling & PCB Development

Design services for injection molds and printed circuit boards for specialized products.

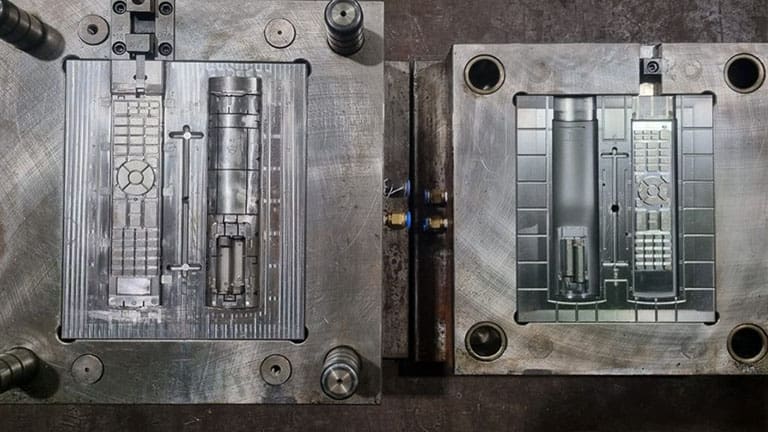

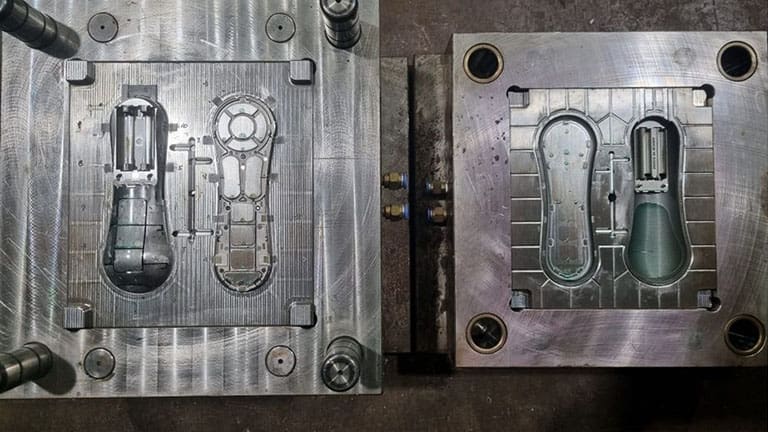

Custom Tooling

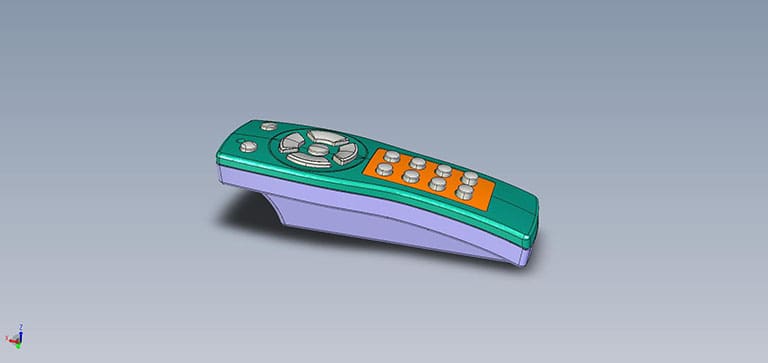

Skip to PCBFor clients with unique product requirements, Celadon can provide full industrial, mechanical and electronic design services for the development of a custom plastic injection molded enclosure (tooling) and a custom printed circuit board assembly (PCBA) for remote control, receiver or other related applications.

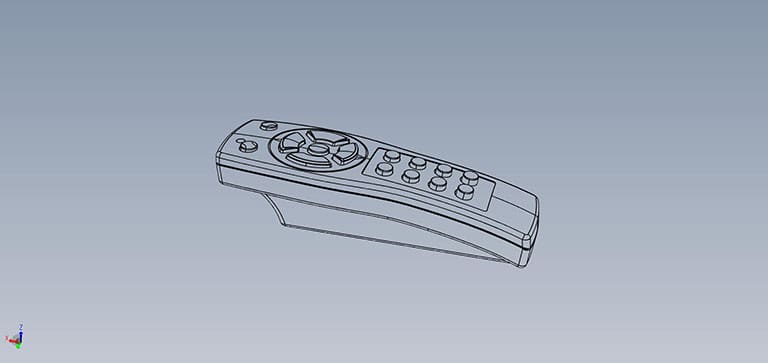

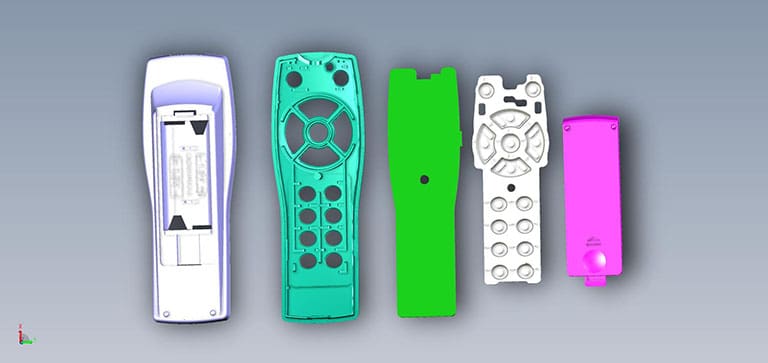

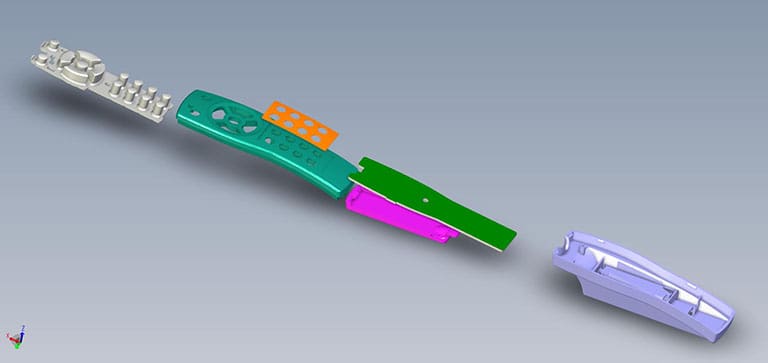

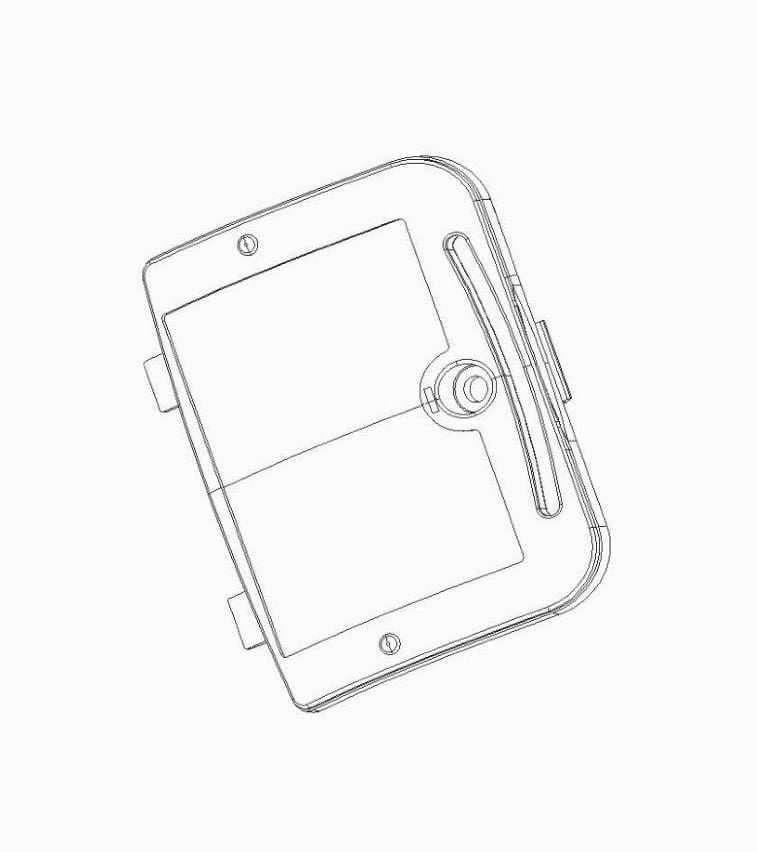

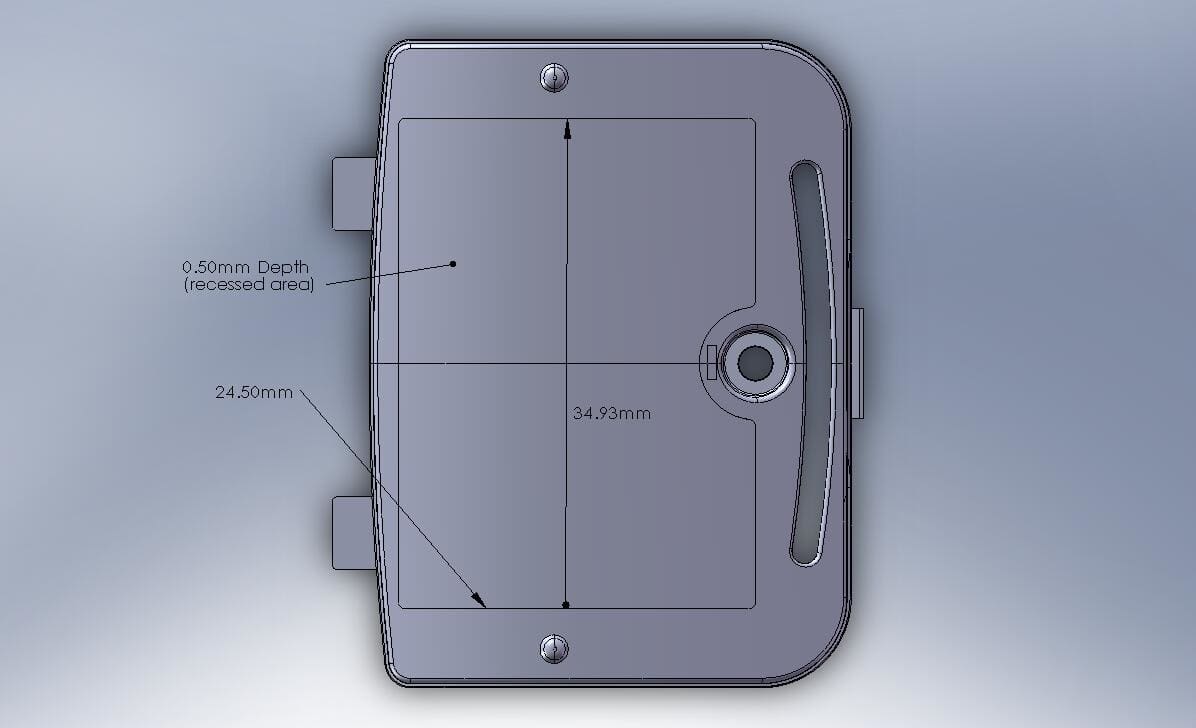

Celadon will work closely with the client to define the size, shape and appearance of the enclosure and provide 3D renderings for concept design and review. If necessary, prototypes can be provided, using a rapid prototyping process like 3D printing or SLA, for evaluation. Once the overall design of the enclosure is approved, the mechanical design will be prepared to detail all of the internal and external features of the enclosure, as well as the design for the keypad, whether plastic, rubber or membrane. After the mechanical design is reviewed and approved, the mold design process will begin and samples will be prepared for the customer to approve for mass production.

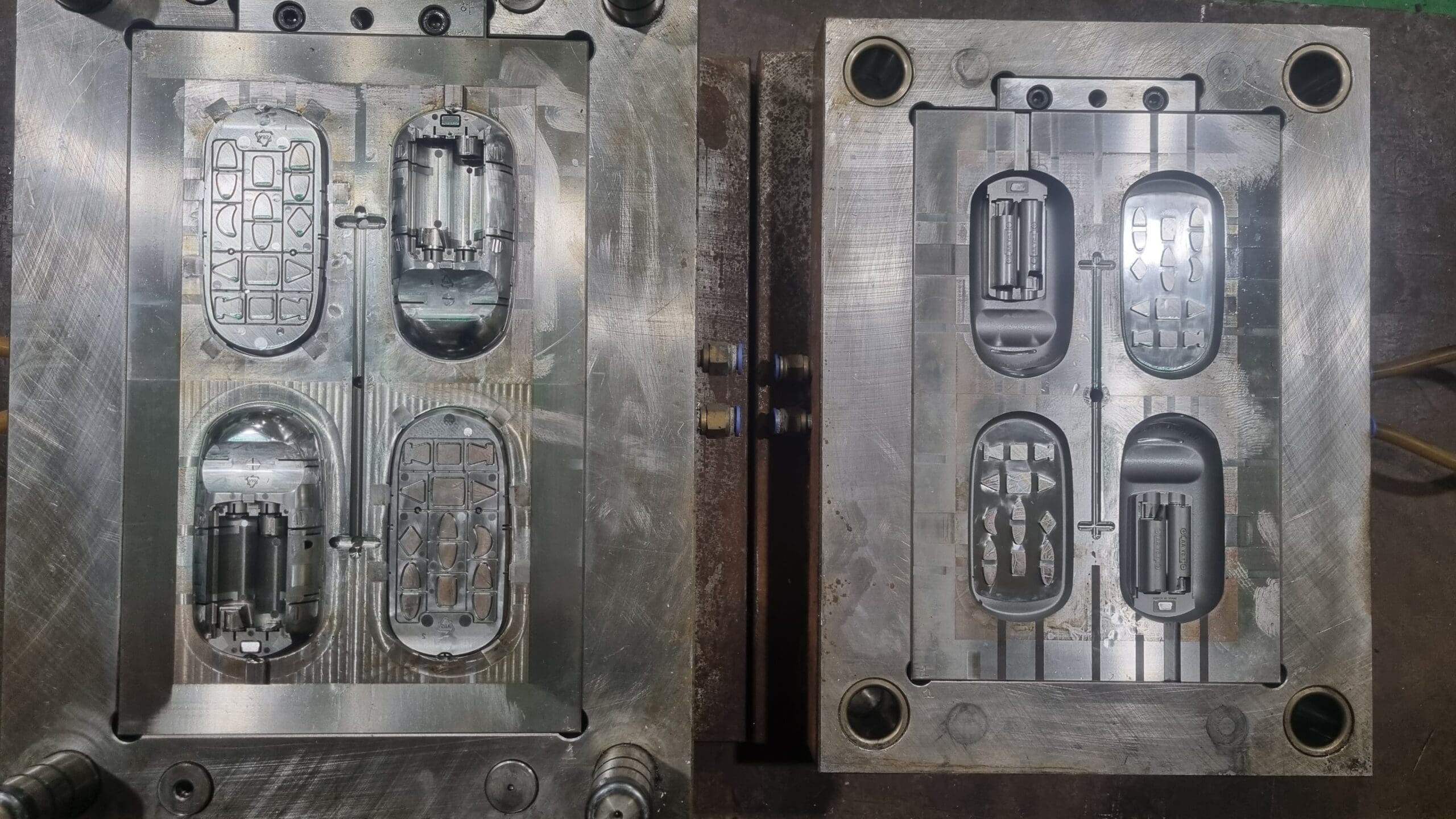

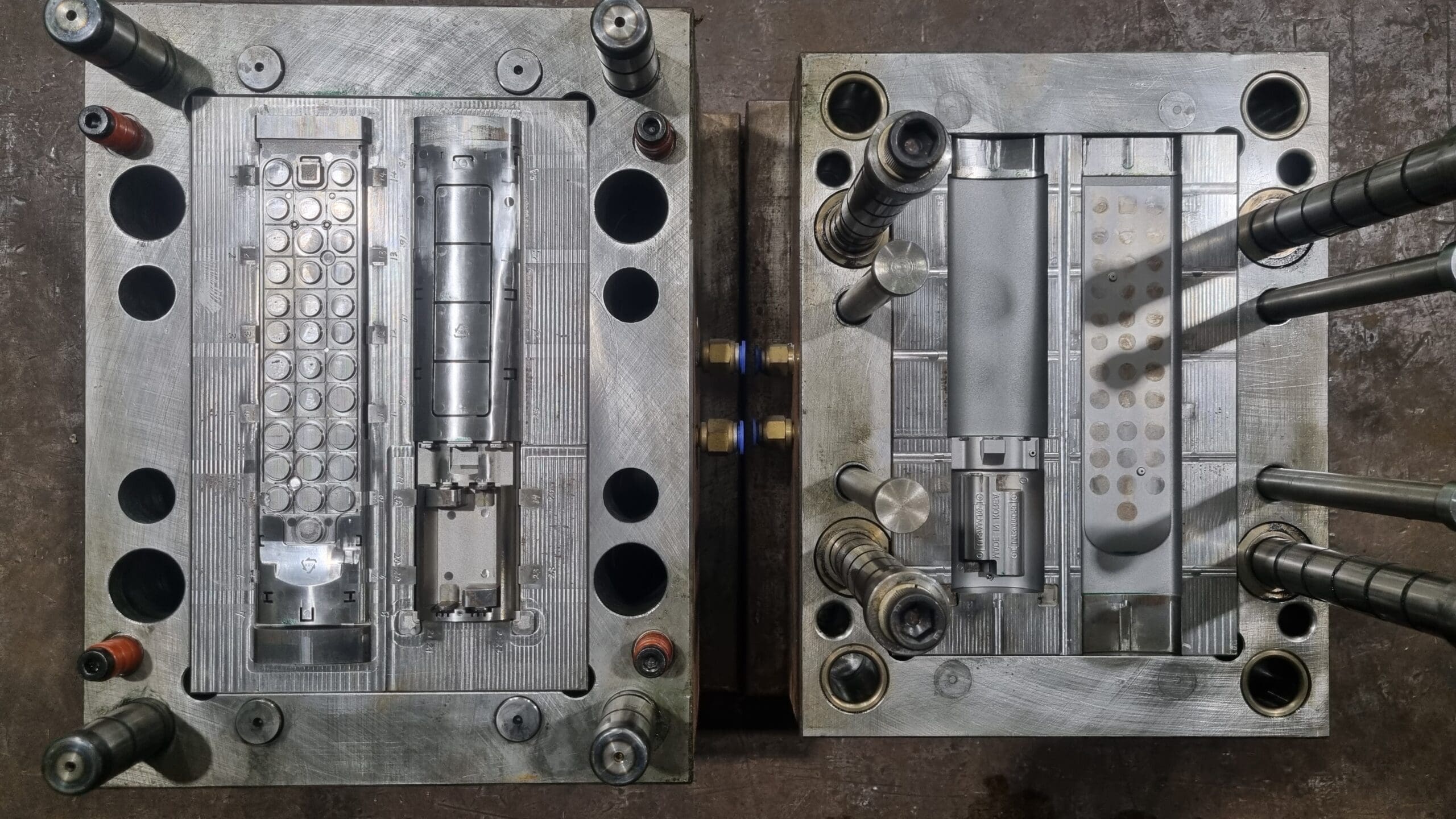

Mold design is based on the overall design of the product. The number of unique parts, the number of different materials and the overall production volumes will be taken into account during the mold design process. For higher volume products, individual molds are made for each part to maximize production efficiency. For lower volume products or to minimize tooling costs, a family mold can be used to consolidate parts of similar size into the same mold. Most tooling is fabricated using NAK80 mold steel and has a useful life of approximately 400,000 – 500,000 shots.

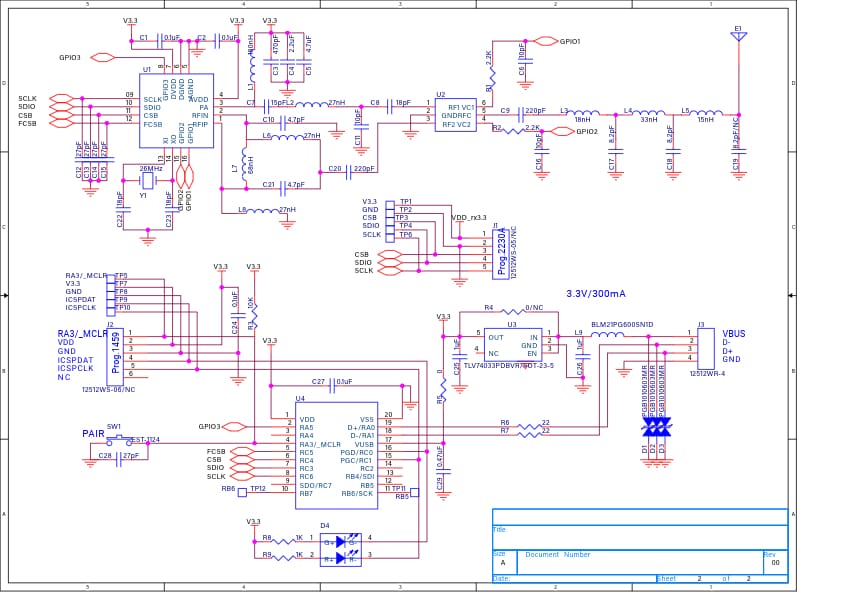

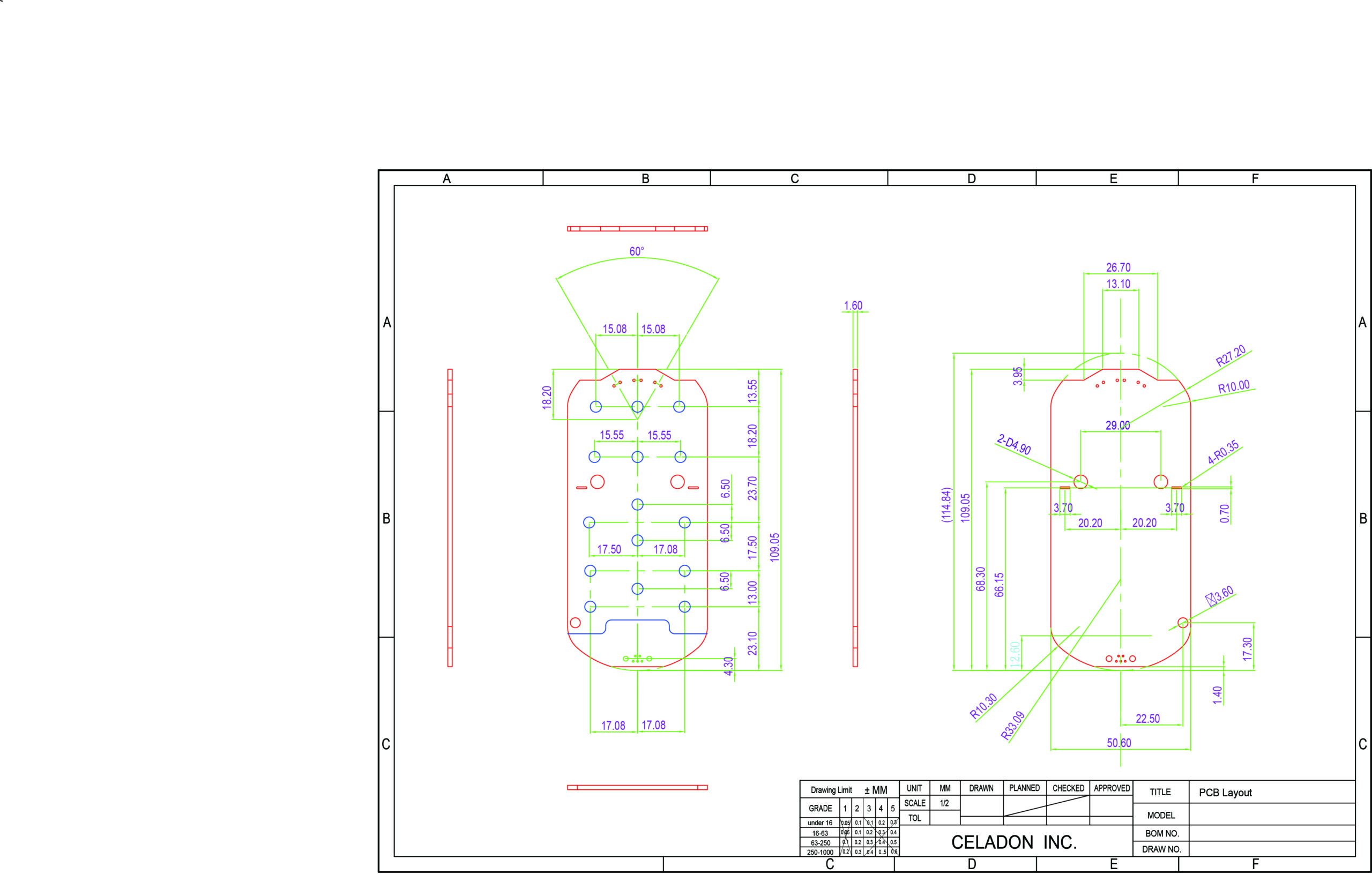

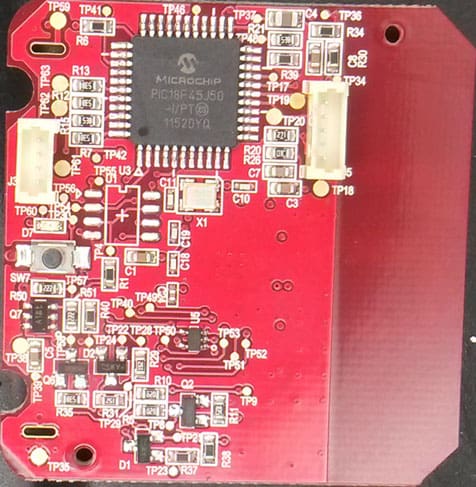

PCB Development

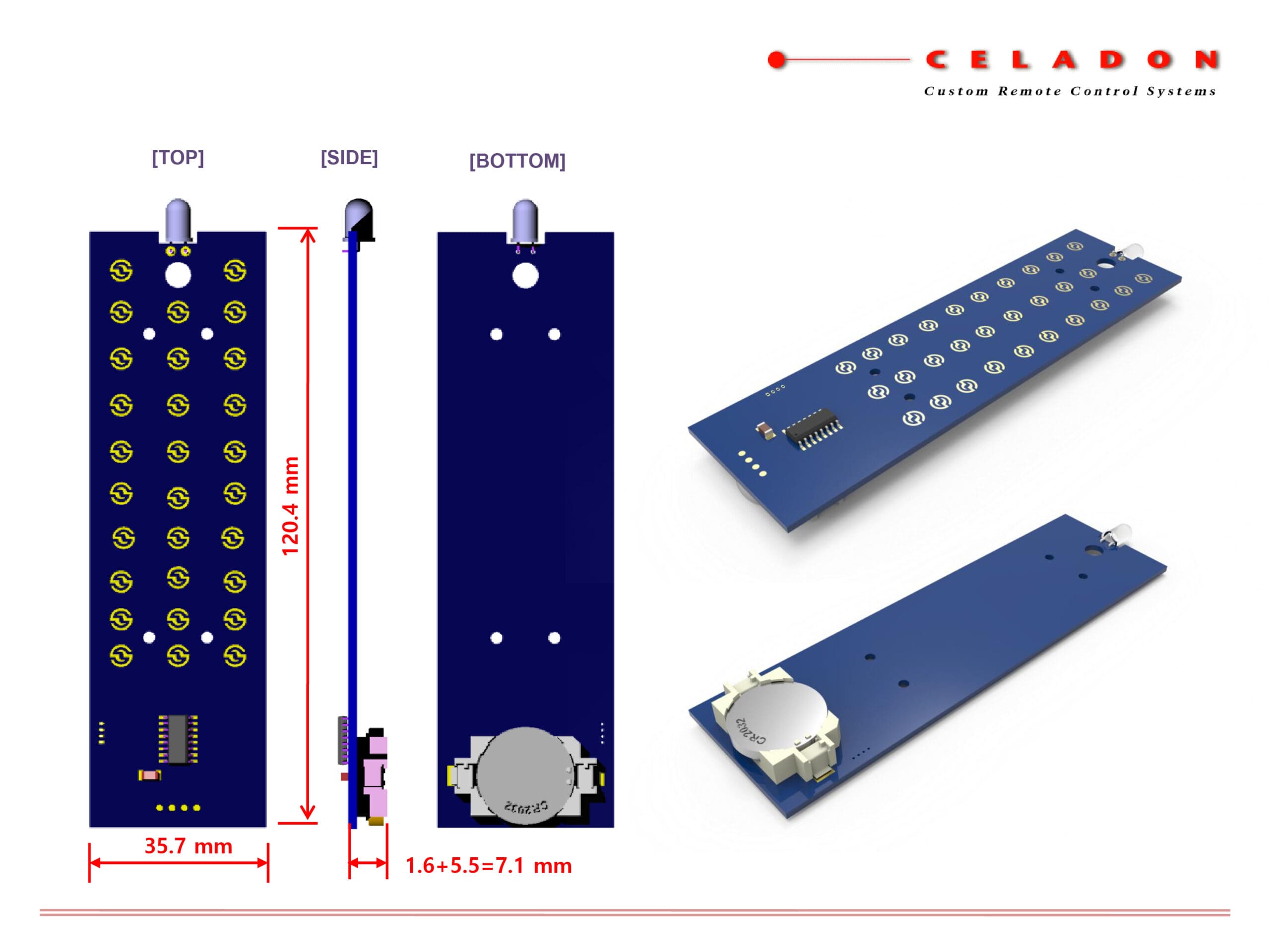

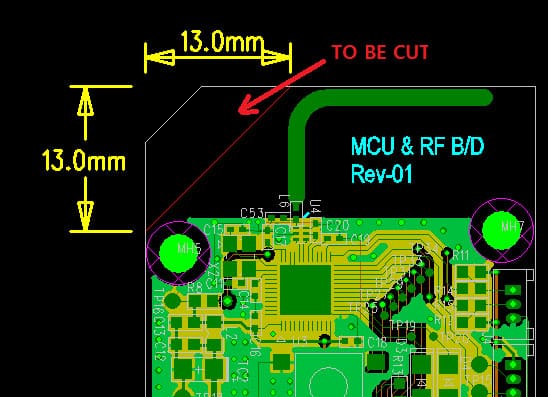

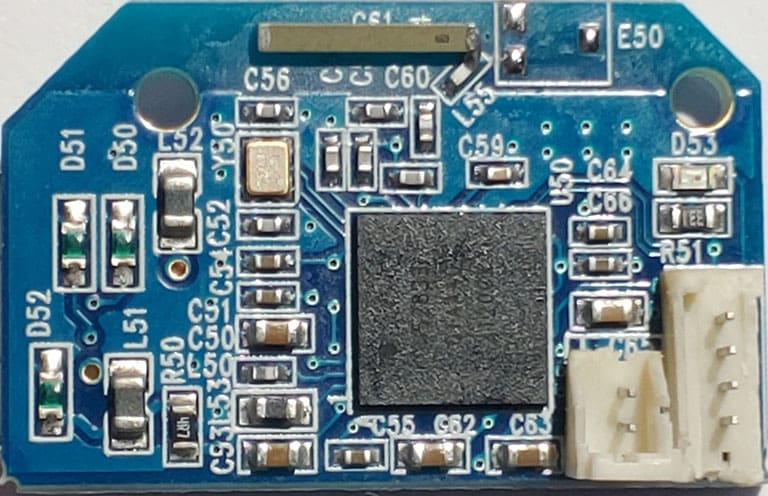

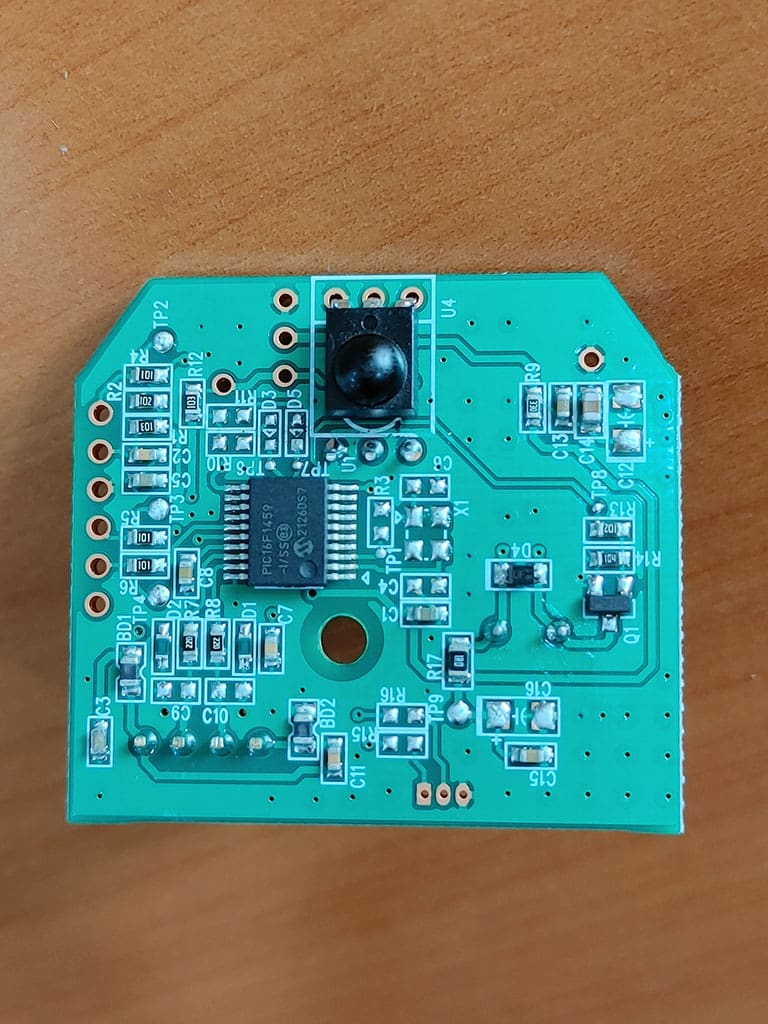

Back to ToolingCustom PCB design involves working closely with the customer to define the functional requirements of the product, determining the optimum microcontroller and other critical components and using best practices to layout the PCB within the confines of the space available within the enclosure. The microcontroller will be programmed, based on the customer approved specifications, and the samples would be thoroughly tested before sending to the customer for final approval for mass production.

Examples of applications for custom tooling and PCB development include Specialized Remote Controls, IoT Devices, Industrial Controllers, Handheld Electronics, Healthcare Products, Educational Products and more.

For more information on Custom Tooling and PCB Development, please complete the form on the Contact Us page to have someone from Celadon contact you to discuss your project in detail.

Additional Information

Let's Work Together

Complete the contact form and submit your product requirements. A representative from Celadon will contact you to discuss your project in more detail.